There are many different hot melt adhesive films, and different types of hot melt adhesive films have different uses. When we inquire about hot melt adhesive films, we often mention a hot melt adhesive film called bare film. For those who don't know, they don't know which type of hot melt film they are talking about.

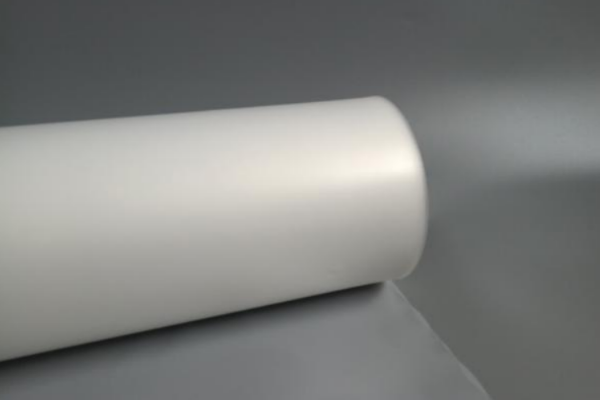

The bare film is just a common name for a substrate-free hot melt adhesive film, which is called bare film because there is no substrate, so it is considered bare substrate by people in the industry. As a substrate hot melt adhesive film, it is usually coated on a layer of release paper or PE release film, which has been used as a backing.

The bare film does not have release paper. PE release film, just a single layer of the adhesive film directly to use, is generally used for continuous laminating equipment composite use, so exempt from the backing process. Because of the omission of release paper or PE release film, the cost of bare film is also much lower than the cost of hot melt adhesive film with the substrate. For some large area laminating enterprises, the cost is also reduced accordingly. It can be said that the development of bare film products has significantly reduced the cost of hot melt adhesive films to make them more competitive in many fields of application.

As for the material, the material of the bare film is not fixed. It can be any composition of hot melt adhesive film. But there are more EVA and TPU films on the market. Other materials are not common, which is related to the film-forming properties of the material. Some materials are more difficult to make a bare film.

Related articles:

How does hot melt adhesive film help to increase the value of a laminating plant?