When it comes to selecting an EVA hot melt film, it is essential to know which features make it the ideal choice for your application. High molecular weight, low temperatures, and good adhesion are all qualities you need to look for in a product. You can further improve its performance by selecting tackifiers with higher polarities, which can help the film achieve optimal adhesion and wetting. To ensure the highest levels of product performance, EVA hot melt adhesive formulations need to be custom-made for the substrates and application techniques. They must also be tailored to the end users' environment.

High molecular weight

A hotmelt film with a high molecular weight EVA is an excellent insulator. It can be used to make a range of electrical and thermal connections. In addition, EVA can be used as the base resin in conductive materials. Some applications include the production of heating bodies, conductive films, elastic electrodes, and computer connectors. However, there are some disadvantages of this material.

EVA is a copolymer of vinyl acetate (VA). The VA content in EVA copolymers is dependent on the polymer's crystalline structure. While VA decreases the crystallinity of the polymer, it also increases its flexibility and transparency. It also has a positive impact on adhesion, so it is often used in toy parts, shoe soles, and cart wheels. Its properties are similar to those of PE, but the VA content makes it better for applications that require higher transparency.

In addition to EVA copolymer, other ingredients in hot melt adhesives may be used to improve the properties of the adhesive. For example, wood rosin derivatives are used as adhesives for plastics, vinyl, and Kraft paper. Hydrocarbon resins are used for adhesives on wood, metal, and Kraft paper. To optimize adhesion and wetting properties, tackifiers are added. Antioxidants are also added to protect the EVA hot melt adhesive while being applied to materials.

Another key factor for the durability of EVA is its polarity. EVA is susceptible to degradation if exposed to harsh environments, such as rain, sun, and wind. Its crystalline structure makes it less durable than polyethylene. Further, it is susceptible to yellowing and condensation, which can negatively impact the performance of a solar PV module. Furthermore, EVA tends to degrade at high temperatures.

While there are disadvantages of using a low-molecular-weight EVA hotmelt film, this material has several advantages. The softening temperature of EVA is relatively high. As long as it's not too hot, it can be used in electrical applications. It is also resistant to UV radiation. Further, EVA is cheaper than other types of rubber, which can lead to a number of electrical problems.

Low temperature

EVA Hotmelt films are generally composed of 30 to 40% EVA copolymer, 20 to 30% tackifier resin, and fillers. The EVA copolymer imparts strength and toughness while the tackifier resin increases wetting and tack. Paraffinic or aromatic hydrocarbon wax reduces viscosity while enhancing tack. The resins are stabilized and add UV resistance or other desired performance properties.

EVA hot melt adhesives can be used to adhere a wide range of cellulosic materials. They are inexpensive, flexible, and have a wide range of properties. Their applications span the packaging, automotive, and woodworking industries. A few of the most common EVA hot melt films are described below. These films are available in various compositions. Those with a higher VA content will have greater transparency, polarity, and extended flexibility, while those with a lower ratio will have greater creep resistance under load.

When selecting the hot melt film for your application, consider its temperature range. If the application is in a very hot environment, high temperatures can damage the delicate material. Low temperature hot melt glues are suitable for applications where high temperatures are undesirable. They are based on synthetic resins, such as EVA copolymers, polyolefins, and polymers. You can find an EVA hot melt film that is best suited for your specific application.

PA Hotmelt Films have the worst low temperature resistance of the three types. This is due to their tendency to brittleness at low temperatures. They will fail to adhere to soft materials, such as clothing fabrics. This can lead to poor product performance. On the other hand, TPU hot melt adhesive films are the best low-temperature films. Their temperature range reaches minus tens of degrees.

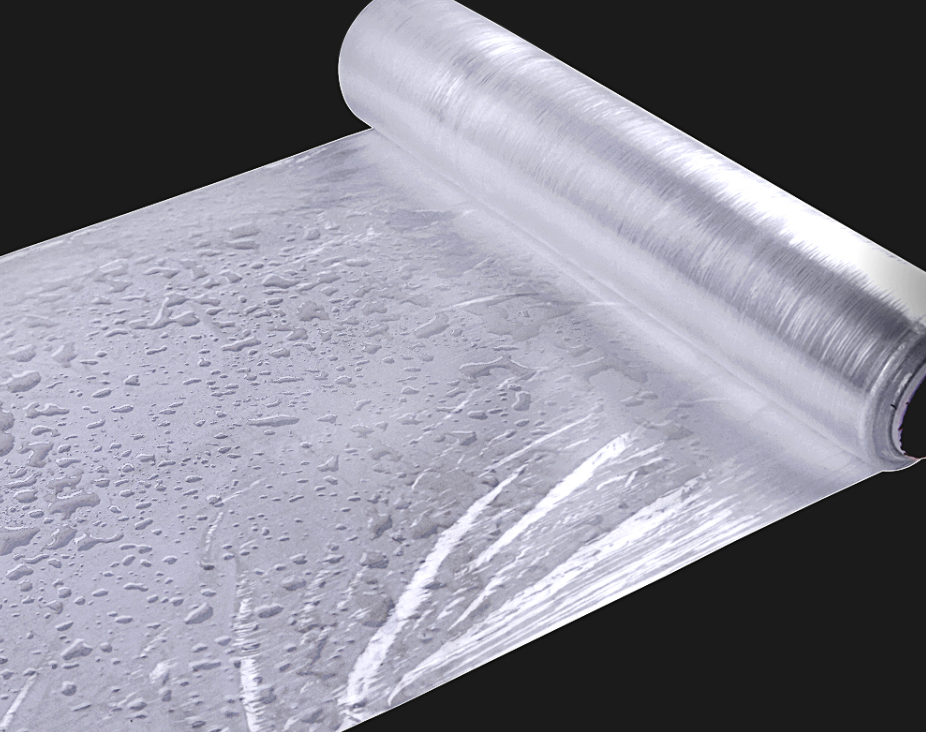

A thermoplastic EVA hot melt film with release paper. It has a low melting point and is easily plasticized at moderate temperatures. These films can be used in a variety of applications, such as in packaging products that contain battery crates. The release paper can be removed, making them suitable for use in battery and 3C product packaging. The material is usually packaged in one roll per carton. So, when it comes to choosing a EVA hot melt film, you'll want to consider the temperature range that works best for you.

Good adhesion

The most important parameters to consider when selecting an EVA hot melt adhesive formulation are open time and tackifier polarity. These properties affect the bonding properties of HMAs and play an important role in the process of application. A higher tackifier polarity will increase the amount of physical adsorption, resulting in a better wetting and adhesion. Good adhesion with EVA hot melt film requires a specific formulation for the substrate, application technique, and end-use environment.

EVA hot melt adhesives are 100% solid Ethylene Vinyl Acetate (EVA) copolymers. These materials are transparent and flexible and are typically categorized by melt index (MI) and melt flow rate (MFT). Most commonly used EVAs have VA content ranging from 19% to 28%, and a MI range of three to two-thousand. Higher VA content results in better transparency, higher polarity, and extended flexibility. A lower MI value indicates higher molecular weight.

The EVA hot melt adhesives are a versatile material for a number of industrial and medical applications. They can bond to a wide range of substrates and can function in a range of temperatures, from -40 degrees F to 160 degrees F. EVA hot melt adhesives are also affordable. Good adhesion with EVA hot melt film is essential for successful production. It is recommended to consult with an expert before applying any EVA hot melt adhesive.

Besides the benefits of hot melt adhesives, these products also offer excellent adhesion properties. A hot melt adhesive can bond foams, corrugated cardboard, and fabrics. Its low melting point is advantageous for the protection of heat sensitive substrates. Hot melt adhesives can also be used for packaging products, electronic devices, and furniture. They are also ideal for automotive and hygiene applications. They are a great choice when applying heat-sensitive products.

Easy processing

EVA hot melt adhesives come in various curing speeds. High speed glues cure faster than low speed glues, and coated paper glues take longer to cure. You should choose the appropriate glue for the project depending on the materials and adhesives you plan to use. To get the best results, master the preparation procedures. Depending on the application, you can choose from two different types of EVA hot melt adhesives: coated paper glue and offset paper glue.

EVA hot melt adhesives are composed of copolymers of ethylene vinyl acetate. EVA copolymers can be formulated into soft or tough pressure-sensitive adhesives. They are often used in semi-structural applications. In general, hot melt adhesives are composed of ethylene vinyl acetate (EVA). The content of vinyl acetate in EVA resins affects their properties. Adhesives with high vinyl acetate content exhibit reduced crystallinity. When the content reaches 50%, crystallinity is lost completely. The choice of EVA resins can also influence recrystallization rates.

EVA hot melt adhesives feature a high ethylene content that increases mechanical strength, block resistance, and paraffin solubility. Vinyl acetate increases flexibility, adhesion, and low-temperature performance. Low-molecular-weight chains of EVA are more flexible, less viscous, and have better heat sealing properties. This material also features a low-temperature range, making it easier to process for various applications.

Another benefit of EVA is that it has a low glass-transition temperature. This makes it suitable for use in high-frequency electronics, but is poor in dielectric properties. High-frequency electronics are best served with polypropylene HMAs. For packaging applications, nearly 50% of EVA HMAs are used. The resin can also be cryogenically ground to yield water-dispersible particles for heat sealing applications.

EVA hot melt adhesive film has an excellent bonding range for fabrics. It is used in a variety of fields, including medical products, sportswear, luggage, and clothing. Its low melting point and high elasticity make it suitable for different applications. Besides being environmentally friendly, hot melt adhesive film is also a strong adhesive and has replaced cheap rough seam LOGO. If you're looking for a fast, easy, and effective way to laminate your fabric, hot melt adhesive film is for you.