Home

> Blog

> What are the distinct advantages of hot melt adhesive films over other adhesive products that deserve attention?

Home

> Blog

> What are the distinct advantages of hot melt adhesive films over other adhesive products that deserve attention?

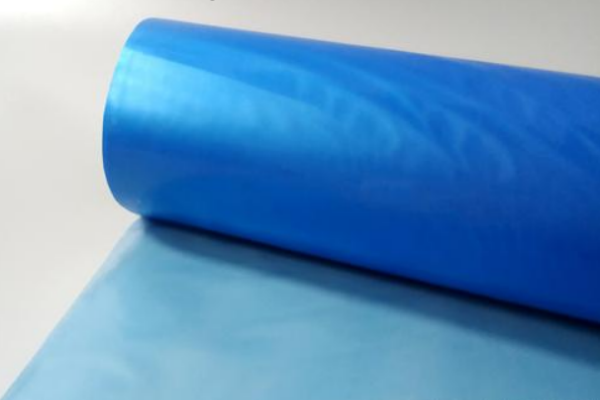

As an organic synthetic adhesive, a hot melt film is a hot melt adhesive. Hot melt films are a minor branch of the synthetic adhesive family, but they have received much attention this year. So, what are the significant advantages of hot melt films over other types of adhesive products?

When the whole society is advocating environmental protection, hot melt adhesive film, which is not harmful to human health, is attracting much attention.

Traditional statistical adhesives require the addition of organic solvents to the glue, most of which are volatile. When they volatilize into the air and are inhaled by the human body, they can produce different degrees of harm. In addition, there is a part of the aldehyde-based adhesive. If the finished product is used for a long time, free formaldehyde will release, and formaldehyde has become an almost universally known hazard.

In the general trend of environmental protection, the use of environmentally friendly adhesives to replace solvent adhesives is the ultimate hope. Hot melt adhesive film is melted by heating. The sizing and infiltration process does not require solvents, so there is no organic solvent volatilization, and there is no free formaldehyde problem. It is a recognized environmentally friendly adhesive. Therefore, hot melt adhesive film is considered the right way in terms of route, which makes it a very promising adhesive species.

Clean sizing is possible, and sizing is easy and more easily mechanized.

Hot melt film is a solid adhesive product in a thin film, unlike liquid adhesives that drip easily during the application, so it is very friendly to the workshop environment. It can achieve clean production, thus abandoning the wet and sticky situation caused by liquid adhesives in the past.

Moreover, the hot melt film only needs a device that can heat and apply a certain pressure. The equipment requirements are not very complicated, and the sizing and laminating can be done in one step, making it very easy to operate. This is an important reason why many people accept hot melt films.

The bonding efficiency is very high because the bonding strength is generated by cooling and hardening itself.

While it is a synthetic adhesive, hot melt film is a thermoplastic material that melts when heated and hardens when cooled to produce adhesive strength. The entire curing process sometimes takes only a few seconds to complete, and the curing speed is quite amazing. Compared to other types of adhesives, hot melt adhesive films are tens or even hundreds of times more efficient. If it is the same to meet the bonding needs, hot melt adhesive film can beat other adhesive weights in front of the production efficiency. Companies will certainly choose hot melt adhesive film. Therefore, the high-efficiency feature is almost the core advantage of hot melt adhesive film, which is the fundamental reason why many enterprise material developers pay attention to it.

These 3 points are the main advantages of hot melt adhesive film. Environmentally friendly! Clean! Efficient! Now it should be clear to you why hot melt adhesive film has attracted so much attention, right?

Related articles:

Hot Melt Adhesive Film Product Introduction

Eva Hot Melt Adhesive Film Product Introduction